CZ-SKD Solutions a.s.

PRESENTATION FOR DOWNLOAD

A tool shop specializing in the production of more technically complex injection molds, providing comprehensive and complete services. Over 30 years of experience in the production of injection molds and plastic parts for our customers.

We offer the development of an ideal injection mold concept with regard to technological requirements for quality and precision of the molded part, requirements for cost-effective production and required tool life with respect to the expected production volume and mold utilization.

01.

VisionWe want to be a prestigious, well-respected and innovative tool shop that makes full use of modern technologies and trends and can handle complex molds and applications. A tool shop that provides complete and comprehensive services and technical facilities to its customers, that works with them closely to create the products they need, and one that is sought after and contacted by leading manufacturers of plastic parts from various branches of industry. We want to be an excellent employer, one where offered positions come with no small degree of prestige; our employees are highly motivated, we train specialists in the field and are aware of our social responsibilities.

02.

MissionWe are a tool shop that develops and produces molds for complex applications and provides complete and comprehensive services to its customers, helping them move forward. We offer comprehensive services from the development of moldings, technical support, construction and production of the mold to delivery of the final product. We provide innovative ideas and follow the latest trends in the construction and production of molds and plastics. We see great potential in innovation and smart solutions to improve the competitive advantage and sustainability of both us and our clients, and we help our clients grow. We don't want to make a name for ourselves on the market with competitive pricing alone; clients need to see that their investment into high-quality tools will pay a return and be worthwhile.

03.

StrategyWe can convince clients that we can handle complex and difficult projects even on a global scale and further strengthen our position as a reliable supplier and partner with comprehensive services. We help innovate products for clients, presenting new ideas and solutions, and in turn contribute to their competitive strength and sustainability. We create and combine synergies between individual fields of industry and support our clients so that they can win projects from their customers and be a part of on-going changes in the automotive industry that keep bringing new and interesting projects and challenges. We try to stand apart from other suppliers; we are proactive and try to do things in a different, better way. Our references show that we are heading in the right direction.

04.

ESG PolicyWe are fully aware that the image of our company is shaped not only by the quality of our products and services, but also by our behavior towards our surroundings, our approach to occupational health and safety, and environmental protection. In the execution of our projects and daily operations, we are committed to complying with all legal regulations applicable to our company. We use sustainable materials in our products that can potentially be reused or recycled at the end of their life cycle. We implement efficient measures in energy consumption, waste generation and reuse, and we prevent emergency situations that could negatively impact the environment. Through effective prevention, we strive to avoid workplace injuries and health hazards. We actively encourage our employees to protect the environment and to adhere to occupational health and safety principles, particularly within the scope of their work responsibilities. We also create conditions for improving the overall work culture and workplace environment.

Services

Competitive advantages

Continuous development and innovation following modern automotive trends are among our main priorities. We actively use 3D printing for prototype plastic parts, but also for the production of injection molds themselves (conformal cooling). We apply special materials to ensure higher production efficiency of molds.

We act as a strategic supplier of molds and parts for our customers, who does not want to succeed only through price, but through quality customized solutions.

Production technology

We have all technologies for the in-house production of injection molds at our disposal.

Development

Our own development and construction, support of customer development. Engineering and consulting services. We use PTC Creo CAD software for development and construction. We use WorkNC 5-axis, ALPHACAM and Kovoprog CAM software to develop machine programs.

Machining

We have all required equipment for the production of injection molds. High-quality, brand-name machines from renowned manufacturers: DMG Mori, Hermle, +GF+, Mitsubishi, Fehlmann. We use all 5 axis for machining to ensure higher efficiency, together with HSC machining and a robotized workplace.

Assembly of molds

We primarily manufacture technically complex molds and molds with complex mechanisms. Highly experienced staff. Production of injection molds with a weight of up to 8 tons. Large assembly hall and our own die spotting press. Laser and TIG welding for repairs of molds. Laser marking of molds.

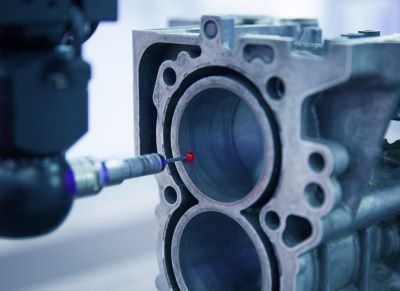

Quality

We hold quality management certificates according to ISO 9001, ISO 14001 and ISO 45001 standards, issued by the renowned company TÜV SÜD. Our metrology department uses two Wenzel CMM machines, an optical microscope, and other calibrated measuring instruments. The company is managed using the Karat information system and the xMost MES system. In production, we apply 5S and TPM standards.

Implemented Applications

- Technically complex parts and applications – water, air and oil coolers, thermostats, fuel, air and oil filters, pumps, suction, etc.

- Molds with complex mechanisms - demolding inner threads, rotation cores

- Replacing metals with plastic

- Visible parts – exterior and interior, headlights

- Overmolding – parts with overmolded components

- Molds for 2K and 3K injection molding

- High-temperature molds – application of PPS, PPA materials, materials with up to 60% glass fibers

- Welded parts – vibration and ultrasonic welding of plastics, welding fixtures

- GIT and Mucell technologies

- Molds for metal injection molding

- Assembly and measuring fixtures, grippers

Gallery of Parts

Our customers