CZ-SKD Solutions a.s.

PRESENTATION FOR DOWNLOAD

A tool shop specializing in the production of more technically complex injection molds, providing comprehensive and complete services. Over 30 years of experience in the production of injection molds and plastic parts for our customers.

We offer the development of ideal injection mold designs that take into account all technological requirements for the quality and accuracy of moldings, cost-effective production and the required service life of the tool in view of expected production volume and utilization of the mold.

01.

VisionWe want to be a prestigious, well-respected and innovative tool shop that makes full use of modern technologies and trends and can handle complex molds and applications. A tool shop that provides complete and comprehensive services and technical facilities to its customers, that works with them closely to create the products they need, and one that is sought after and contacted by leading manufacturers of plastic parts from various branches of industry. We want to be an excellent employer, one where offered positions come with no small degree of prestige; our employees are highly motivated, we train specialists in the field and are aware of our social responsibilities.

02.

MissionWe are a tool shop that develops and produces molds for complex applications and provides complete and comprehensive services to its customers, helping them move forward. We offer comprehensive services from the development of moldings, technical support, construction and production of the mold to delivery of the final product. We provide innovative ideas and follow the latest trends in the construction and production of molds and plastics. We see great potential in innovation and smart solutions to improve the competitive advantage and sustainability of both us and our clients, and we help our clients grow. We don’t want to make a name for ourselves on the market with competitive pricing alone; clients need to see that their investment into high-quality tools will pay a return and be worthwhile. Our clients include prestigious TIER1 suppliers in the automotive industry and leaders in their fields; they are often global players. In the defense sector, we work closely with the prestigious Česká zbrojovka a.s., a leader and global player in its field, and we also share a link through shareholders.

03.

StrategyWe can convince clients that we can handle complex and difficult projects even on a global scale and further strengthen our position as a reliable supplier and partner with comprehensive services. We help innovate products for clients, presenting new ideas and solutions, and in turn contribute to their competitive strength and sustainability. We create and combine synergies between individual fields of industry and support our clients so that they can win projects from their customers and be a part of on-going changes in the automotive industry that keep bringing new and interesting projects and challenges. We try to stand apart from other suppliers; we are proactive and try to do things in a different, better way. Our references show that we are heading in the right direction.

Services

Competitive advantages

We consider continuous development and innovation following current automotive trends to be one of our priorities. We actively use 3D printing for prototype plastic parts, as well as separate production of injection molds. We strive to be a strategic supplier of molds and parts for our customers, whose main focus is not on price but on high-quality, custom solutions.

Production technology

We have all technologies for the in-house production of injection molds at our disposal.

Machining

We have all required equipment for the production of injection molds. High-quality, brand-name machines from renowned manufacturers: DMG Mori, Hermle, +GF+, Mitsubishi, Fehlmann. We use all 5 axis for machining to ensure higher efficiency, together with HSC machining and a robotized workplace.

Machines

Assembly of molds

We primarily manufacture technically complex molds and molds with complex mechanisms. Highly

experienced staff. Production of injection molds with a weight of up to 8 tons. Large assembly hall

and our own die spotting press. Laser and TIG welding for repairs of molds. Laser marking of molds.

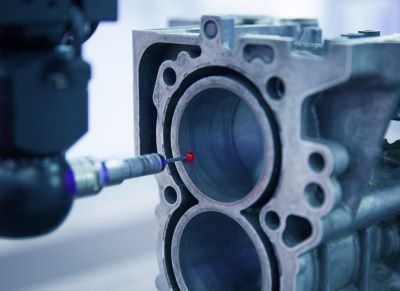

Quality

We are the holder of an ISO 9001 quality certificate from renowned TÜV SÜD. Our own CMM

machines by Wenzel, microscope. Company management in the Karat information system. Application of 5S and TPM standard

Implemented Applications

- Technically complex parts and applications (water coolers, air and oil, thermostats, fuel, air and oil filters, pumps, suction,...)

- Molds with complex mechanisms - demolding inner threads, rotation cores

- Replacing metals with plastic

- Visible/exposed parts (exterior and interior, headlights)

- Overmolding – parts with overmolded components

- Molds for 2K injection

- High-temperature molds – application of PPS, PPA materials, materials with up to 50% GF

- Welded parts (vibration and ultrasound welding of plastics, welding tools/jigs)

- GIT and Mucell technologies

- Assembly and measuring tools

Gallery of Parts

Our customers